Local Pickup FAQ's

Hover to zoom

1 Of 5

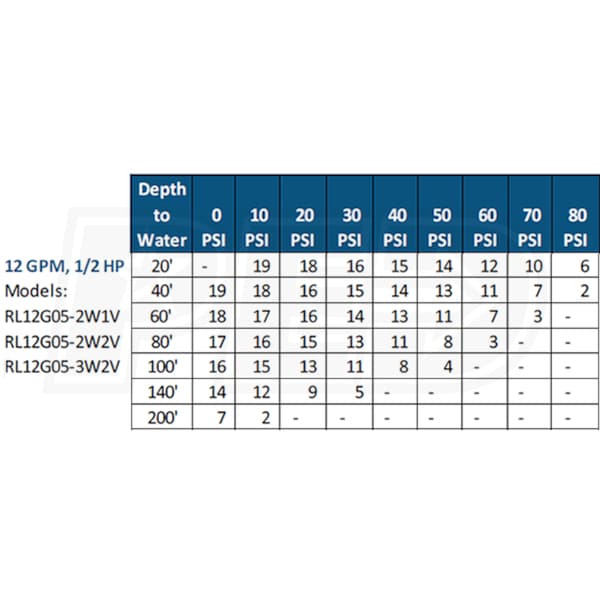

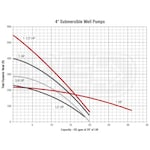

Red Lion 12 GPM 1/2 HP Deep Well Submersible Pump (3-Wire 230V) w/ Control Box

Model:

14942405

+

Share This Product

Recommended Accessories

Expert Recommended Accessories

Selected by Jim, our Expert

Required Accessories

9

These accessories are required to properly setup/install this product.

Optional Accessories

10

Features

Inlet Size

N/A

Style

Deep Well

GPM

12 Gallons

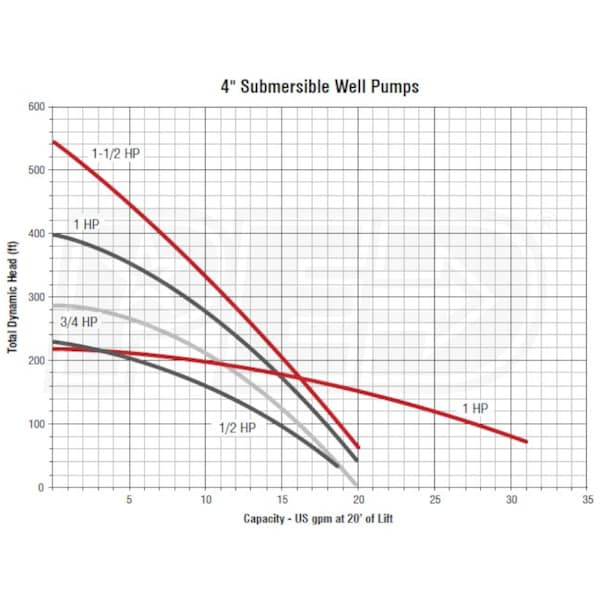

- 4" Submersible Deep Well Pump

- Ideal for use with 4" I.D. or larger wells

- Powered By Industry Standard 3-Wire 230V Motor

- Proven superior quality & performance ensuring quiet operation

- Hex Rubber Bearing w/ Extra-Large Surface

- Provides shaft stability and multiple flow channels

- Keeps small particles such as sand away from bearing surfaces

- Built-In Check Valve

- Prevents back-flow and ensures system pressure

- Built-In Suction Screen

- Helps to prevent debris from clogging impellers

- 1-1/4" NPT Thermoplastic discharge head

- Provides full-flow performance without the risk of corrosion

- Includes Red Lion Control Box

- Eliminates confusion for control box selection

Specifications

14942405

General Information

Product Category

Water Pump

Motor

Voltage

240 Volt Single-Phase

Wire

3-Wire

Pump

Gallons Per Minute

12 Gallons

Outlet Diameter

1-1/4 Inch

Housing Material

Stainless Steel

Impeller Material

Plastic

Maximum PSI

80

Total Head Lift

200 Feet

Submersible

Yes

Engine

Continuous Operation

Yes

Horsepower

0.5 HP

Overview

Product Category

Water Pump

Weight

25 Pounds

Made in USA

No

Consumer Warranty

3 Years

UPC

010121141810

Additional Model Numbers

RL12G05-3W2V, 14942405

Reviews

(88)

Red Lion 14942405 Reviews & Ratings

Product Q&A

(9)

Product Questions

Answered by Jim, the Water Pump Expert

Does this pump have a rope tie-off to prevent losing it in the well?

David M.

from Arkansas

March 14, 2018

I have read that this pump utilizes a Franklin motor, is this true?

Ken K.

from Texas

May 10, 2017

In have 4 inch ID pvc well casing ..your product description says it will fit. What is the width of the pump?

Vince

from Indiana

June 16, 2016

I plan to replace a 30 yer old pump that is at 200 ft. and lower the new pump to 250 ft in a 400 ft deep well. Will I need to a check valve mid way up as well as at the well head?

Ken G

from California

July 27, 2015

what guage wire should be run to this pump if set at two hundred feet

Billy

from West Virginia

June 22, 2014

I am converting from a jet pump to a submersible pump. I am installing a new pressure tank and am ordering a RL 12G05-3W2V pump from you.

What else will I need for my conversion? Wire, etc?

The pump specs say the outlet is 1 1/4". Is the water line that connects to the fitting 1"?

Paul F

from Kansas

May 02, 2014

what parts are involved with submersible pumps that can fail and breakdown or if it doesn't work you just have to replace the entire pump?

Sal

from New York

January 22, 2014

Can a pump saver and a float switch be used with thiscontrol box that comes with the pump. Thanks

Kevin

from Idaho

April 14, 2013

what is the purpose of the control box and can it be eliminated?

Armand

from Ohio

July 09, 2012

How-To Articles

How to Pick the Perfect Well Pump

Using centrifugal force, a well pump shoots water from its underground reservoi...

Priming Your Well Pump

Well pumps have been around for centuries, but the days of using a bucket and r...

How to Pick the Perfect Specialty Water Pump

All water pumps are built for the same purpose: moving water. But there are sp...

Manuals

Ask A Question!

*Required Fields

+

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Thank You For Submitting Your Question

Your submission has been sent successfully. Please give our experts up to two business days to respond.

Media Gallery

Red Lion 12 GPM 1/2 HP Deep Well Submersible Pump (3-Wire 230V) w/ Control Box

Customer Review Images